Diaphragm Pump

1, no shaft seal, no leakage, the flow passage is spacious, so the delivery of particles, high viscosity [viscosity up to 10,000 centipoors], volatile and corrosive medium, will not cause environmental pollution and harm to personal safety.

2, no rotating parts, through the good performance, allowing through the maximum particle diameter of 10 mm. No shear flow of liquid, pump itself parts wear small. Small damage to transport material, can transport sludge and living organisms such as small fry.

3, do not need irrigation water, self-priming ability, suction range up to 7 meters, long time dry breathing, no damage to the pump. Once the pump is overloaded, it will automatically stop, and when the load returns to normal, it can automatically start up and run, with self-protection function (electric pump does not have this function).

4, pneumatic pump head up to 50 meters, electric pump up to 30 meters, the maximum outlet pressure up to 0.6 mpa. Electric pump does not have this function, the import need to install the control valve.

5, pneumatic pump can be immersed in the medium to work, no power through, safe and reliable [electric pump without this performance].

6, pneumatic pump does not need power supply, more suitable for flammable, explosive occasions of medium transport.

Piston pump

Piston PUMP IS SUITABLE FOR HIGH pressure, small flow occasions, especially when the flow is less than 100 meters 3/ hour, discharge pressure is greater than 9.8 MPA, more shows its higher efficiency and good operation performance. It has good suction ability, can suction a variety of different media, different viscosity of liquid. Therefore, it is widely used in petrochemical industry, machinery manufacturing industry, papermaking, food processing, pharmaceutical production and other aspects. Low medium speed piston pump with low speed, can be operated by human and driven by animal force, suitable for rural water supply and small irrigation.

Peristaltic pump

A peristaltic pump consists of three parts: the driver, the pump head and the hose. The fluid is isolated in the pump pipe, the pump pipe can be replaced quickly, the fluid can be retrograde, dry operation, low maintenance cost characteristics.

A peristaltic pump is like squeezing a fluid-filled hose with a finger pinch, and the fluid moves forward as the finger slides forward. The peristaltic pump works the same way with rollers instead of fingers. Fluid is pumped by alternately squeezing and releasing the pump’s elastic delivery hose. It’s like squeezing a hose with two fingers. As you move your fingers, negative pressure builds up inside the tube and fluid flows.

A peristaltic pump is a section of pipe between two rollers that forms a “pillow” of fluid. The volume of the pillow depends on the inner diameter of the pump pipe and the geometry of the rotor. The flow rate depends on the product of three parameters: the speed of the pump head, the size of the “pillow” and the number of “pillows” produced by each revolution of the rotor. The size of the pillow is generally constant (except when pumping particularly viscous fluids).

Compared with the pump with the same rotor diameter, the pump with a larger “pillow” volume produces a larger volume of fluid transported by the rotor in each turn, but the pulsation degree is also larger. This is similar to the case of membrane valves. And produce smaller “pillow” volume of the pump, the rotor each turn of the fluid volume is small; Moreover, the small “pillow” formed quickly and continuously makes the flow of fluid smoother. This works in a similar way to a gear pump.

- no pollution: fluid only contact pump pipe, do not contact the pump body;

- high precision: repeat precision, high stability precision;

- low shear force: is an ideal tool for conveying shear sensitive, erosive fluid;

- good sealing: with good self-priming ability, can idling, can prevent reflux;

- simple maintenance: no valves and seals;

- with two-way equivalent flow transmission capacity; No liquid empty operation will not cause damage to any parts of the pump; Can produce up to 98% vacuum degree; Without valves, mechanical seals and packing seals, there are no leakage and maintenance factors; It can easily transport solid, liquid or gas-liquid mixed phase fluid, allowing the diameter of the solid contained in the fluid to reach 40% of the inner diameter of the tube element; Can transport all kinds of grinding, corrosion, oxygen sensitive characteristics of the material and food; Only the hose is the part that needs to be replaced, and the replacement operation is very simple. In addition to the hose, the conveying product does not contact with any parts.

Gear pump

Gear pump is a rotary pump that depends on the change and movement of the working volume formed between the pump cylinder and the meshing gear to transport liquid or pressurize it. It consists of two gears, the pump body and the front and rear covers. When the gear rotates, the volume of the space on the side of the gear is increased from small to large, forming a vacuum, and the liquid is sucked in. The volume of the space on the meshing side of the gear is reduced from large to small, and the liquid is squeezed into the pipeline. The suction cavity and the discharge cavity are separated by the meshing line of two gears. The pressure of the outlet of the gear pump completely depends on the resistance of the pump outlet.

centrifugal pump

The basic structure of centrifugal pump is composed of six parts: impeller, pump body, pump shaft, bearing, sealing ring and stuffing box.

- the flow direction of water along the centrifugal pump is along the impeller axial suction, perpendicular to the axial outflow, that is, the flow direction into and out of each other 90°.

- Because the centrifugal pump depends on the impeller inlet to form vacuum water absorption, so before starting, it must be poured into the pump and water absorption pipe, or pumped with a vacuum pump to discharge the air to form a vacuum, and the pump shell and water absorption pipe must be strictly sealed, no air leakage, otherwise it is not a vacuum, it can not absorb the water.

- because the impeller inlet is impossible to form an absolute vacuum, so the centrifugal pump suction height can not exceed 10 meters, and the water flow through the suction pipe along the loss, the actual allowable installation height (pump axis from the height of the suction water surface) is far less than 10 meters. If the installation is too high, it does not absorb water; In addition, because the mountain area than the plain atmospheric pressure is low, so the same pump in the mountain area, especially in the high mountain area installation, the installation height should be reduced, otherwise can not suck up water

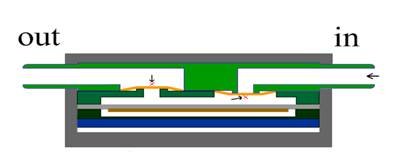

Electromagnetic pump

The electromagnetic PUMP is a liquid PUMP that combines the power and the PUMP body. The working principle of the electromagnetic pump is similar to the ordinary solenoid valve. It takes alternating current as the working power, and the current forms an alternating fixed magnetic field through the electromagnetic winding, which interacts with the moving pump body to drive the vibration of the pump body and promote the liquid output.

- Electromagnetic pump is a kind of mature technology and widely used pump products, with compact structure, high output pressure, no leakage, small volume, relatively low price, low output flow and other characteristics. Compared with the commonly used centrifugal (impeller) pump, the output pressure is 2 to 10 times higher, compared with the plunger pump, the volume is reduced by more than 1 times.

- Performance indicators of the electromagnetic pump (water medium, room temperature) : output pressure 0.3 ~ 1.2 mpa, flow 1 ~ 5 liters/minute, input power 10 ~ 120 watts.

- Application field of electromagnetic pump: beverage drinking machine: Features: the instant beverage is quickly made into drinks, such as coffee, orange juice, Gao Le higher. Steam CLEANER: Features: provide steam output pressure at 0.8 mpa, for industrial cleaning grease, dirt to provide a convenient, simple, efficient tool. Teeth flusher: Features: WITH a high pressure of 2 KPA, 3000 pulses of water per minute to rinse and clean teeth and gums, to achieve oral health care, reduce dental caries. Spray humidifier: high efficiency, large capacity air humidification · Pressurized filter: Features: improve input pressure, improve filtration efficiency. For example, household pure water machine. · Metering pump: Features: good regulating performance, wide regulating control range. Carpet cleaner: Spray steam into the surface of the carpet, decompose dirt, and then the dirt away, compared to vacuum cleaner better effect.